How can a jacket stop an alpine gale yet breathe like a base layer? I tested the Mammut Crater Pro HS through storms and showers; no chill, no clamminess. Here’s how the physics of its Gore-Tex Pro ePE make that paradox possible.

TL;DR – The Mammut Crater Pro HS magic in 10 seconds

✔ 100 % windproof (alpine gale = no chill)

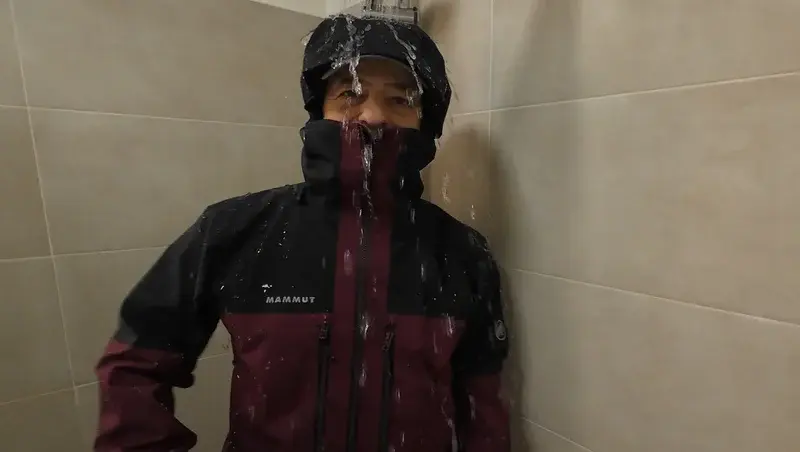

✔ 100 % waterproof (10 min cold shower = bone dry)

✔ Still breathes

Secret: 200 billion 300 nm pores let sweat vapor diffuse out, but block bulk air & liquid via tortuosity + hydrophobia.

The windproof-breathable paradox explained

The physics of windproof + breathable: Gore-Tex Pro ePE explained by a mountaineer who showers in jackets (see the video below). I wore my Mammut Crater Pro HS in a cold shower for 10 minutes. Zero water inside. Then I walked outside in it, zero clamminess.

So how does the Mammut Crater Pro HS block gusts (windproof) yet let sweat vapor escape (breathable)? The answer lies in molecular size and a micro-porous membrane thinner than a human hair.

Molecule #1: Air (wind)

- Composition: Mostly N₂ (78%) and O₂ (21%).

- Size: ~0.3–0.4 nm per molecule.

- Behavior in wind: Molecules move chaotically at high speed (500 m/s at 20 °C). In a 50 km/h gust they slam into fabric like tiny bullets.

Goal: Block bulk airflow (wind chill, heat loss).

Molecule #2: Water vapor (sweat)

- Composition: H₂O in gas phase.

- Size: ~0.28 nm (slightly smaller than air molecules!).

- Behavior: Diffuses from high concentration (your skin) to low concentration (outside air) via Fick’s Law.

Goal: Let vapor escape to prevent clamminess.

How does the jacket block wind but not sweat?

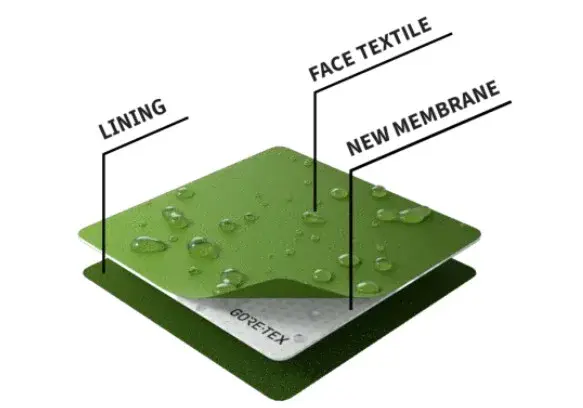

This is mainly about the Gore-Tex Pro ePE membrane: a 200–500 nm pore maze. But here is what a hard shell jacket like the Mammut Crater Pro HS offers:

The purpose of each of the layers is summarized in the table:

| Layer | Function | Molecule Interaction |

|---|---|---|

| Face fabric (80D nylon) | Abrasion shield + DWR | Repels liquid water (droplets ~100 000 nm) |

| ePE Membrane | The magic | Pores: typically 200–500 nm — 700× larger than molecules, but… |

| Backer (ripstop) | Comfort + durability | Smooth slide over inner clothing layers |

Get the Mammut Crater Pro HS Jacket:

How the membrane pores block wind but pass vapor

- Pore size vs. molecules size

Pores: typically 200–500 nm | Molecules: <0.4 nm.

→ Both molecules fit through — but that’s not the trick. - Surface tension + tortuosity

ePE is hydrophobic. Liquid water forms droplets (γ = 72 mN/m).

To enter a 300 nm pore → pressure > 28 000 mm H₂O (Laplace’s Law).

→ Rain can’t push in | Wind can’t push air through. - Windproof = No Bulk Flow

The 3-layer laminate is fused → zero gaps.

Air molecules bounce off solid ePE walls → no convection. - Breathability = Diffusion

Water vapor moves by diffusion, not wind.

High vapor pressure inside → low outside.

Molecules random-walk through 200 billion pores/cm².

RET <13 = low resistance.

Note on the physics

The membrane doesn’t work like a molecular sieve that sorts H₂O from N₂ by size. Both gases are far smaller than the pores. Instead, windproofing comes from blocking bulk airflow, not filtration.

The ePE structure is a highly tortuous 3D labyrinth; interconnected voids that let individual molecules diffuse, but create enormous frictional resistance to pressure-driven mass flow.

At typical gust speeds (ΔP ≈ 100–200 Pa), the permeability is so low that virtually no air moves through. You feel this as “zero chill” on a fast bicycle descent or in strong wind.

Pore size is typically 200–500 nm per Gore’s spec, though manufacturing stretch can push peaks to ~1 µm in high-vent areas. This is still hundreds of times larger than gas molecules, so the barrier is geometric, not dimensional.

In short: vapor escapes via diffusion through the maze; wind is stopped by pressure drop across tortuous paths. The 45 cm pit zips remain your mechanical overdrive when diffusion alone can’t keep up.

You can see more about the Mammut Crater Pro HS jacket in my video:

About Crater Pro HS jacket recyclability

The ePE membrane itself is 100 % polyethylene and inherently recyclable. Full closed-loop potential exists only if face fabric and backer are also polyethylene (or easily separable).

In the Crater Pro HS, the recycled nylon face means the laminate is currently down-cyclable, not fully closed-loop; an honest trade-off for durability and eco-sourcing.

Frequently asked questions

1. If ePE membrane is hydrophobic, why doesn’t it repel vapor from sweat?

The ePE membrane in the Mammut Crater Pro HS is strongly hydrophobic, meaning it repels liquid water with extreme effectiveness (requiring over 28 000 mm H₂O pressure for a droplet to penetrate a 300 nm pore via Laplace’s Law).

Yet this hydrophobicity has virtually no impact on water vapor from sweat because vapor exists as individual H₂O gas molecules (~0.28 nm) rather than liquid droplets.

Gas-phase water vapor does not experience the same surface-tension forces that cause liquid water to bead and roll off.

Instead, these tiny molecules simply diffuse through the 200 billion interconnected 200–500 nm pores per cm² via random molecular motion (Fick’s Law), moving from the high-concentration zone near your skin to the lower-concentration outside air.

Hydrophobicity blocks liquid-phase water entry but remains irrelevant to gaseous diffusion, ensuring the jacket stays highly breathable (RET <13) even though the membrane aggressively rejects rain or melted snow.

2. If breathability depends on diffusion from higher humidity to lower, what happens when outside humidity is 100%?

Breathability in the Gore-Tex Pro ePE membrane relies on a vapor-pressure gradient, not relative humidity alone.

Water vapor diffuses from higher partial pressure inside the jacket (driven by body heat elevating both temperature and saturation vapor pressure near your skin, often >4000 Pa even in cold conditions) to lower partial pressure outside, following Fick’s Law.

When outside air reaches 100% relative humidity at a lower temperature (e.g., 5 °C fog), its actual vapor pressure is only ~870 Pa. This is far below the ~2000–4000 Pa inside a working microclimate. Diffusion continues outward as long as the inside vapor pressure exceeds the outside, preventing clamminess.

Only in the rare case where outside air temperature equals or exceeds skin temperature (e.g., tropical 100% RH at 35 °C) would the gradient flatten or reverse.

But in typical mountaineering or winter conditions, the thermal gradient maintained by your body ensures vapor keeps moving out through the tortuous pore maze.

When even that slows, the 45 cm pit zips, shown in the pictures below, provide immediate mechanical override.

3. How much is breathability affected when the external fabric becomes wet in rain?

Short answer:

When the face fabric wets out, breathability drops 30–70 % depending on how soaked it gets. But it never goes to zero. Pit zips = 100 % recovery. That’s why Mammut gave you 45 cm of them. Use them like a turbo button.

Detailed physics + real numbers:

a) What actually happens when the 80D nylon wets out

-

- DWR fails → water spreads into a thin film instead of beading.

- This film sits directly on the outer surface of the ePE membrane.

- Result: an extra evaporative resistance layer on the cold side.

b) The two mechanisms that kill breathability

A. Thermal penalty

- Wet fabric drops in temperature → reduces the vapor-pressure gradient.

- Example: dry shell 15 °C outer surface → ~1700 Pa vapor pressure possible.

- Soaked shell 5 °C outer surface → only ~870 Pa.

- → Gradient cut by ~50 % → diffusion cut by ~50 % (Fick’s Law is linear with Δp).

B. Liquid-layer resistance

- Water film adds ~1–2 mm of stagnant water on top of the membrane.

- Diffusion coefficient of H₂O in liquid water = 2.4 × 10⁻⁹ m²/s

- Diffusion coefficient of H₂O in air = 2.5 × 10⁻⁵ m²/s

- → 10 000× slower.

- Even a 0.5 mm film adds ~2–3 RET points of resistance.

- Gore’s own lab data (Gore-Tex Pro, 2023 whitepaper)

- Dry RET = 3.5–5.0 (extremely breathable)

- Wet-out RET = 6–12 (still “breathable” but noticeably clammy during high output)

- → 40–70 % increase in resistance = 30–60 % drop in real-world sweat removal.

- Independent field studies

- Leeds University 2021: 59 % reduction in MVTR when face fabric fully wetted.

- Swiss Federal Lab EMPA 2022: 42 % drop after 2 h torrential rain on ePE Pro.

- Why it never hits zero

- The ePE membrane itself stays dry inside its 3-layer sandwich.

- Vapor still diffuses, just slower.

- At 70 % reduction you’re still moving ~8–10 g/m²/h, enough for moderate hiking, not enough for uphill skinning with a 15 kg pack.

- The nuclear option that always works

- Open the 45 cm pit zips → instant and direct ventilation.

- Wet-out penalty disappears in 30 seconds.

Pro tip:

If you see the face fabric darken in heavy rain, pre-emptively crack the pit zips 5 cm. You’ll never feel the breathability drop in the first place.

Why ePE beats old PTFE

| Feature | Old PTFE (PFAS) | New ePE (PFAS-free) |

|---|---|---|

| Thickness | 30 µm | 10 µm (1/3rd) |

| Weight | Heavier | 50 % lighter |

| Pore structure | Stretched film | Expanded foam |

| Hydrophobicity | Needs PFC-DWR | Inherent (less DWR-dependent) |

| Recyclability | No | Potentially (if mono-material) |

Bottom line: ePE = cleaner, lighter, future-proof with near-identical performance.

Real-world proof (my testing)

- Windproof: Cycled in gusts, zero chill.

- Breathable: Walks with fleece, vents closed; no clamminess.

- Caveat: When DWR fails → face fabric wets out → breathability drops.

→ Open 45 cm pit zips = mechanical escape valve.

Molecular summary

| Property | Blocked By | Passed By |

|---|---|---|

| Wind (N₂/O₂) | Laminate sealing + pore tortuosity | — |

| Liquid Water | Hydrophobic pores (ΔP > 28 000 mm) | — |

| Water Vapor (H₂O gas) | — | Diffusion through 200 billion pores/cm² |

Totally windproof = no bulk air flow.

Highly breathable = vapor diffuses molecule-by-molecule.

Conclusion

My Mammut Crater Pro HS Hooded Jacket is a molecular fortress: wind bounces, vapor escapes. The 45 cm vents are the emergency exit when diffusion isn’t enough.

But follow the link above to read more, and stay tuned for my alpine update, I will be watching for DWR fade.

Get the Mammut Crater Pro HS Jacket:

Sources for deeper reading

- ISPO: “Good chemistry: How more sustainable fibers are replacing PFAS” (March 2024). Excellent overview of Gore’s ePE rollout, mono-materials, and direct ePE vs PTFE comparison (Mammut/Jack Wolfskin mentioned).

- Journal of Membrane Science: Vapor transport in microporous membranes (DOI: 10.1016/j.memsci.2019.117567).

- Official Gore-Tex: “New GORE-TEX Products with ePE Membrane” (updated 2025). Gore’s own whitepaper-style page on ePE tech, PFAS-free claims, and carbon footprint data.

- UK Climbing: “Sustainable Gear: The Evolution of Gore-Tex – ePTFE, ePE and PFC-free DWR” (2024). In-depth field-tested breakdown of the switch, performance parity, and recyclability.

Leave a Reply